US Add��Orkan18.LLC.9284 talway cir Boynton

����������beach.fL33472

Tel��+001-8556752618

Mobile��(001)5613126473

Cel��+86-158-1188-2441

Phone: +86-755-25423447

Fax: +86-755-25417648

Email: jackdu999@yahoo.com

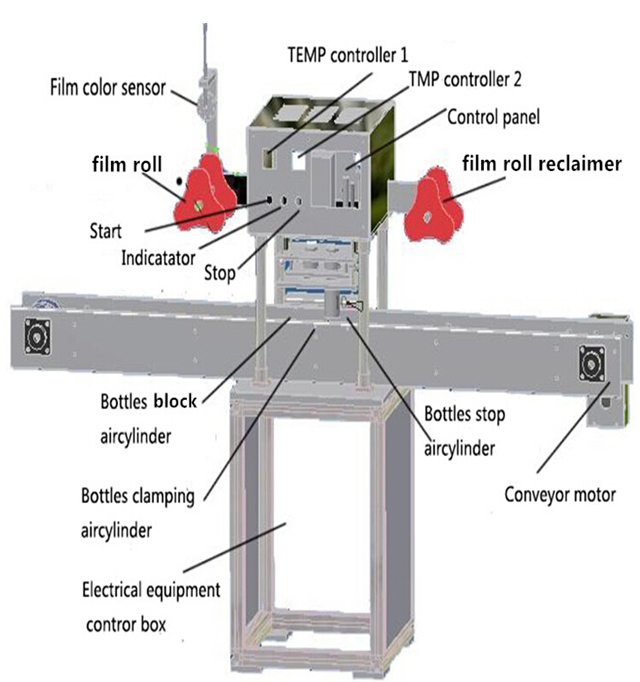

Videos illustration of model YX-FS30A three heads jars wide mouth bottles sealing machine

The automatic sealing machine is designed based on various needs from customer. With beautiful shape, exquisite structure, it is easy to operate and performs solid sealing.

Integrating light, electricity and air into one, featured by touch screen user-machine interface, constant temperature heating, in-built sharp blades, air pressure as power, instant down pressing for cutting sealing film, nice-looking sealing,electriceye label sensing, auto waste material discharging, convenient operation, and low fault rate, it is a nice equipment for box and cup sealing.

Notes for use of model YX-FS30A automatic jars sealing machine:

1, Make sure grounding is well connected to ensure the safety of using electricity.

2, In case any accident happens, press down the emergency stop button first, and then turn off the power supply.

3, When the machine is in operation, do not put your hand into the machine.

4, Make sure the power supply is in conformity with the machine requirement.

5, Make sure air supply is firstly connected before any operation of the machine.

As below there listed for the basic parameter of automatic jars sealing machine model YX-FS30A:

air pressure:0.8Mpa 0.1m3/min

power:3300W Voltage: 380V/3Phase/60hz

dimension:1650×550×1350mm

weight:185kg

sealing scope:Φ70-Φ150mm

sealing speed:1500-1800bot/h

sealing temperature:50-300temperature

Temperature form and deviation: Automatic constant temperature, a deviation of ± 3 temperature

►Air pressure requirements

4 to 8 kg of air pressure is best for the machine. Every day when operation finishes, both the electricity and air must be turned off.

►Maintenance and cleaning

1, Regulaly Clean the working side of heating panel to prevent the unevenness of working side of pressure head from affecting the sealing.

2, Regularly clean tooth blade to keep it sharp. The correct way of cleaning is to turn off power first and then to take down the film pressing frame by unscrewing the four screws on it. Finally do the cleaning with cloth and alcohol.

3, Oil the mechanical transmission parts regularly with lubricating oil. It there is obvious noise on any transmission part, disassemble the cover and oil the part where noise is found.

4, Oil the sliding chute every half month.

Using Method

1. Use of Temperature controller.

Turn on the power switch, set the temperature of temperature controller to 160-200 degrees, (the temperature has been set before factory delivery. However, if the temperature is not enough, only slight adjustment is needed, but the temperature should never be too high). Preheating time is about 5-10 minutes and sealing can be proceeded when it reaches preset temperature.

2. Adjustment for the man-machine interface

When the interface is started, it displays “welcome to use automatic sealing machine”, then for the manual operation interface, each movement can be checked before officially starting operation, such as : Bottles IN, Bottles OUT, Bottles Clamping, Sealing, Film Rolling, on the interface right side is "parameter setting", if the parameters needed to be reset, directly touch click on the line of words and a small digital keyboard will pop out for you to set the required value, and press ENTER to save and exit, the machine’s factory default setting of sealing time of is 0.7S, film rolling length is 5 PM, the others are 0.

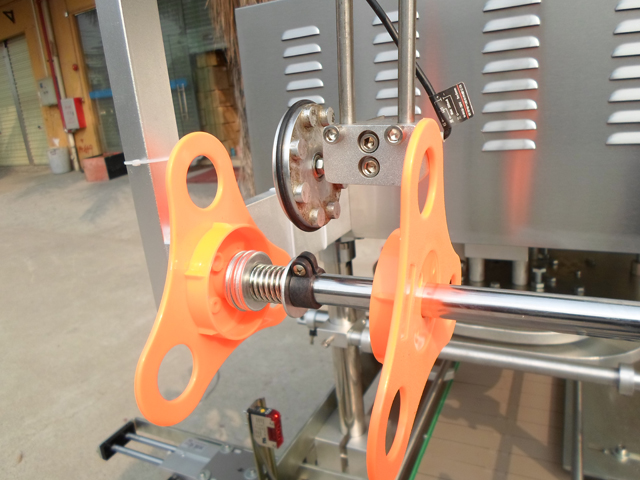

3. Use of Film Roll Counter

The Film Counting Meter is the controller for the length of the film roll. When it is to be operated by the user-machine interface, notices should be given that the film roll must be assembled stable and well, with rubber wheels pressing on the film roll, before any operation.

Sealing Film Material & Temperature

1, PE (polyethylene) 170 degrees

2, PP (poly propylene ethylene) 170-200 degrees

3, PS (polystyrene) 180 degrees

4, Easy tear film 120-170 degrees

Defaults &trouble-shooting

A, Sealing is not closed or not solid

1, clean the heating plate working side and corresponding working side of pressing head.

2, Adjust to the suitable temperature and sealing time. Sealing time is 0.7 S.

3, Use high quality sealing film or cups.

4, Check to see whether the bottle clamp mold is deviated or not, and adjust the jar mouth and heating plate to be in alignment.

B, Sealing Film Cutting not complete and clean

1, clean the tooth blade

2, replace the damaged tooth blade

3, air pressure is less than 4 kg/CM

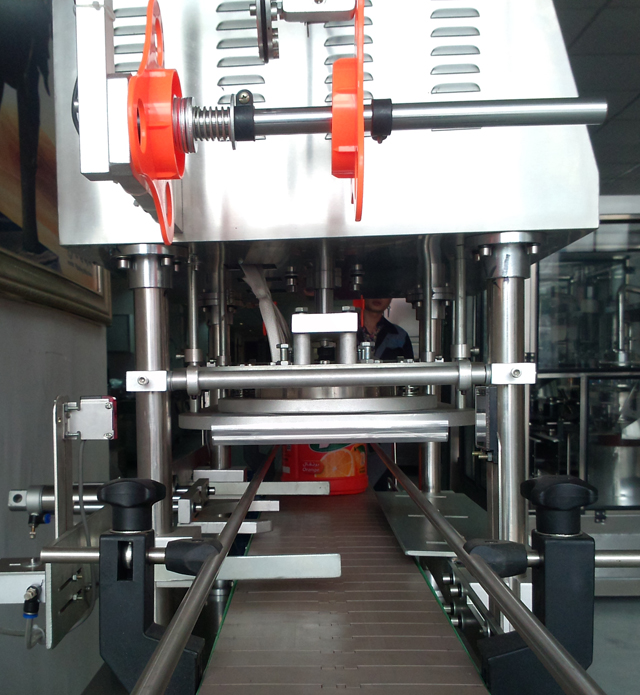

rolls of films &Jars sealing samples

Wooden crate packing for automatic sealing machine before ocean shipping

® ALL RIGHTS RESERVED BY PENGLAI CORP

Related video

|

|

ENGLISH

ENGLISH